FRP Pultruded Grating Dab-demiska/iska caabinta Kiimikada

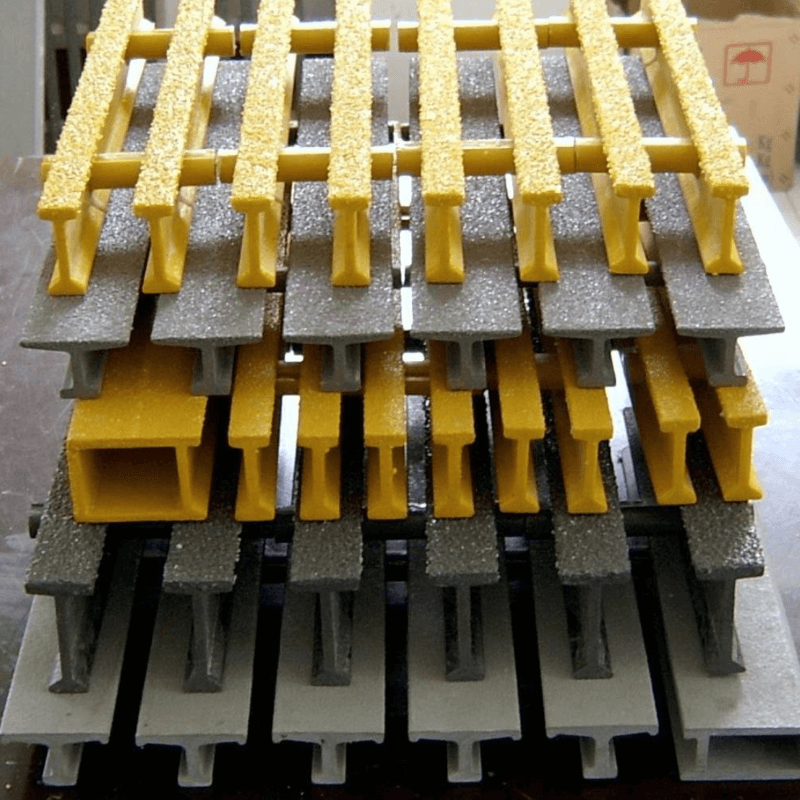

Qaybo ka mid ah bandhigyada daaqsinka leh ee FRP ee la qurxiyey:

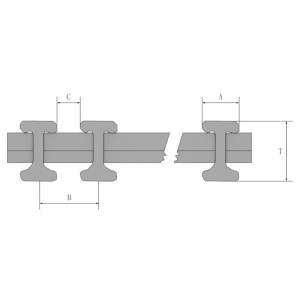

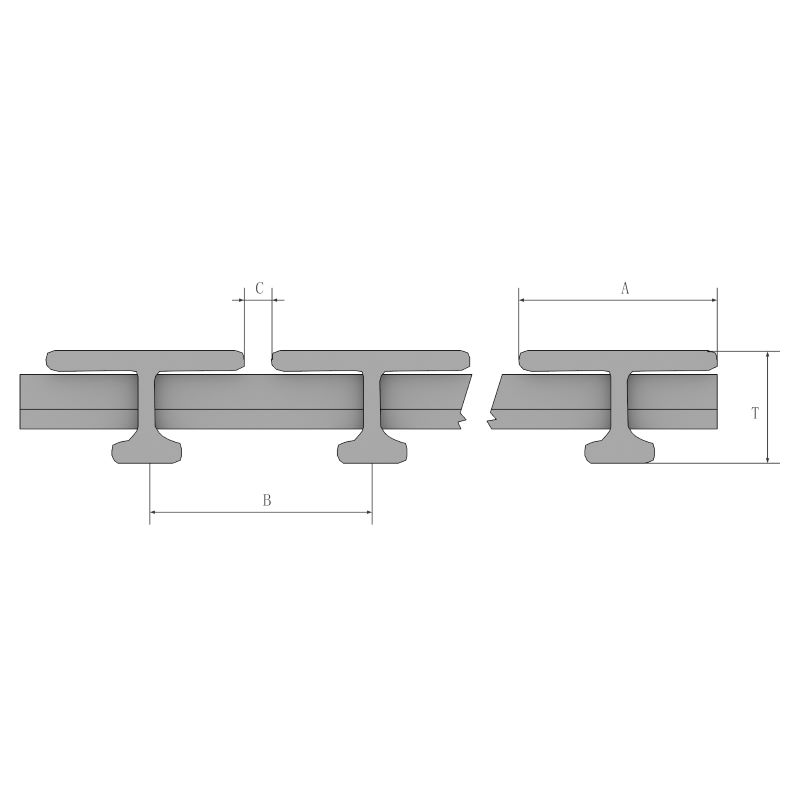

| I-5010 | 50 | 15 | 25 | 10 | 40 | 28.5 |

| I-5015 | 50 | 15 | 30 | 15 | 50 | 24.2 |

| I-5023 | 50 | 15 | 38 | 23 | 60 | 20.1 |

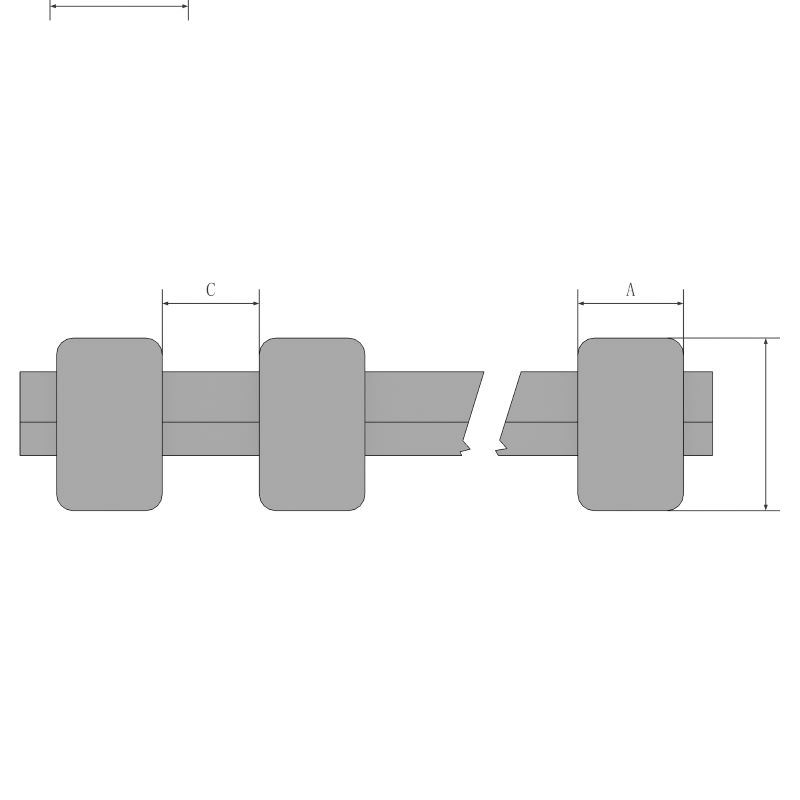

| T-2510 | 25 | 38 | 43.4 | 5.4 | 12 | 15.6 |

| T-2515 | 25 | 38 | 50.8 | 9.5 | 18 | 13.9 |

| T-2520 | 25 | 38 | 50.8 | 12.7 | 25 | 13.6 |

| T-2530 | 25 | 38 | 61 | 19.7 | 33 | 11.2 |

| T-3810 | 38 | 38 | 43.3 | 5.2 | 12 | 19.6 |

| T-3815 | 38 | 38 | 50.8 | 12.7 | 25 | 16.7 |

| T-3820 | 38 | 38 | 61 | 23 | 38 | 14.3 |

| T-5010 | 50 | 25.4 | 38.1 | 12.7 | 33 | 21.8 |

| T-5015 | 50 | 25.4 | 50.8 | 25.4 | 50 | 17.4 |

| H-5010 | 50 | 15 | 10 | 10 | 40 | 63 |

| H-5015 | 50 | 15 | 15 | 15 | 50 | 52.3 |

| H-5020 | 50 | 15 | 23 | 23 | 60 | 43.6 |

| Nooca jeexjeexa jeexan | Dhererka (mm) | Balaadhka cidhifka sare (mm) | Inta u dhaxaysa (mm) | Balaadhka nadiifinta (mm) | Aagga furan (%) | Miisaanka la qiyaasay Kg/㎡ |

| I-2510 | 25 | 15 | 25 | 10 | 40 | 17.8 |

| I-2515 | 25 | 15 | 30 | 15 | 50 | 15.2 |

| I-2523 | 25 | 15 | 38 | 23 | 60 | 12.2 |

| I-3810 | 38 | 15 | 25 | 10 | 40 | 22 |

| I-3815 | 38 | 15 | 30 | 15 | 50 | 19.1 |

| I-3823 | 38 | 15 | 38 | 23 | 60 | 16.2 |

| I-3010 | 30 | 15 | 25 | 10 | 40 | 19.1 |

| I-3015 | 30 | 15 | 30 | 15 | 50 | 16.1 |

| I-3023 | 30 | 15 | 38 | 23 | 60 | 13.1 |

Doorashooyinka Nidaamyada Resins ee FRP:

Hagaha ikhtiyaarka resins:

| Nooca Resin | Xulashada xabagta | Guryaha | Iska caabinta Kiimikada | Dab-demiska (ASTM E84) | Alaabta | Midabada hadalka | Heerkulka ugu sarreeya ℃ |

| Nooca P | Phenolic | Qiiqa Hoose iyo Iska caabinta Dabka Sare | Aad u Wanaagsan | Fasalka 1, 5 ama ka yar | Qaboojiyay oo Barooray | Midabada hadalka | 150 ℃ |

| Nooca V | Vinyl Ester | Iska caabinta Daxalka Sare iyo Dib u Celinta Dabka | Aad u fiican | Fasalka 1, 25 ama ka yar | Qaboojiyay oo Barooray | Midabada hadalka | 95℃ |

| Nooca I | Polyester-ka isophthalic | Iska caabinta Daxalka Fasalka Warshadaha iyo Dab-demiska | Aad u Wanaagsan | Fasalka 1, 25 ama ka yar | Qaboojiyay oo Barooray | Midabada hadalka | 85℃ |

| Nooca O | Ortho | Iska caabinta Daxalka Dhexdhexaadka ah iyo Dib u Celinta Dabka | Caadi ah | Fasalka 1, 25 ama ka yar | Qaboojiyay oo Barooray | Midabada hadalka | 85℃ |

| Nooca F | Polyester-ka isophthalic | Caabbinta Daxalka Darajada Cunnada iyo Dib u Celinta Dabka | Aad u Wanaagsan | Fasalka 2, 75 ama ka yar | La qaabeeyey | Brown | 85℃ |

| Nooca E | Epoxy | Iska caabin daxalka oo aad u wanaagsan iyo dab-demiska | Aad u fiican | Fasalka 1, 25 ama ka yar | Barooran | Midabada hadalka | 180℃ |

Midabada hadalkaMarka loo eego bay'ada iyo codsiyada kala duwan, ee la doortay ee resins kala duwan, waxaan sidoo kale ku siin karnaa xoogaa talooyin ah!

Xabagta phenolic (Nooca P)Doorashada ugu fiican ee codsiyada u baahan dab-demiska ugu sarreeya iyo qiiqa sii daaya ee hooseeya sida warshadaha saliidda, warshadaha birta, iyo sagxadaha.

Vinyl Ester (Nooca V): u adkeyso jawiga adag ee kiimikaad ee loo isticmaalo kiimikaad, daaweynta qashinka, iyo dhirta cawska.

Xabagta isphthalic (Nooca I): Doorasho fiican oo loogu talagalay codsiyada halka ay kimikadu firdhiso iyo daadinta ay tahay dhacdo caadi ah.

Heerka Raashinka xabagta isofthalic (Nooca F): Waxay ku habboon tahay warshadaha warshadaha cuntada iyo cabitaanka kuwaas oo soo gaadhay deegaan nadiif ah oo adag.

Ujeedada Guud ee Xabagta Lafaha (Nooca O): beddelka dhaqaalaha ee vinyl ester iyo alaabta resins isophthalic.

Epoxy Resin (Nooca E):bixiyaan sifooyin farsamo oo aad u sarreeya iyo iska caabin daal, qaadashada faa'iidooyinka resins kale. Kharashyada caaryada waxay la mid yihiin PE iyo VE, laakiin kharashyada alaabta ayaa ka sarreeya.

Shaybaarka tijaabinta awooda alaabta:

Qalabka tijaabada ah ee aadka u fiican ee FRP profiles jeexan iyo FRP-sharafyada qaabaysan, sida tijaabooyinka dabacsanaanta, tijaabooyinka xawliga, tijaabooyinka cadaadiska, iyo tijaabooyinka wax burburiya. Marka loo eego shuruudaha macaamiisha, waxaanu samayn doonaa imtixaanada bandhigyada & kartida ee alaabta FRP, ilaalinta diiwaannada si loo dammaanad qaado xasilloonida tayada muddada dheer. Waxaan hubin karnaa in tayada ay qancin karto shuruudaha macaamiisha si degan si looga fogaado dhibaatooyinka iibka kadib aan loo baahnayn.

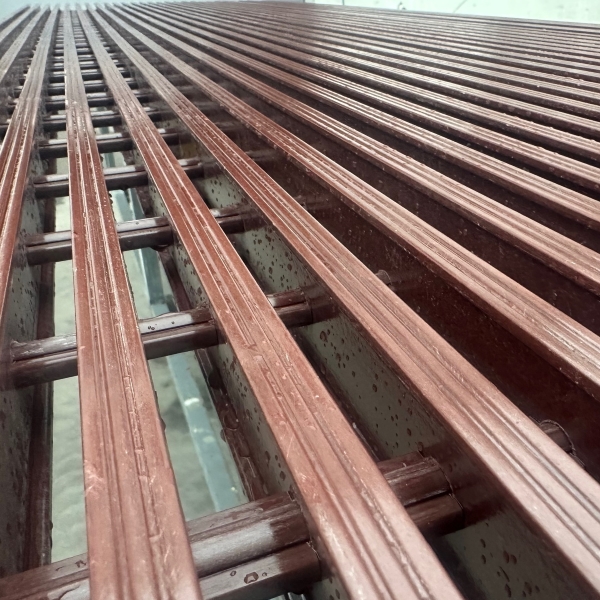

SINOGRATES@FRP Pultrusion Grating

Habka pultrusion waa habka wax soo saarka ee soo saarida dhererka joogtada ah ee qaababka qaab dhismeedka polymer la xoojiyay oo leh qaybo joogto ah. Walxaha ceeriin waa isku dhafka dareeraha ah ee xabagta (resins,fillers iyo additives) iyo dhar dabacsan oo xoojinaya fiberglass rovings. Nidaamku wuxuu ku lug leeyahay jiidashada alaabtan ceeriin (halkii la riixi lahaa, sida kiiska extrusion) iyada oo la adeegsanayo birta kulul ee samaynaysa dhinta iyadoo la isticmaalayo qalab jiidis joogto ah.

Alaabta la xoojiyay waxay u qaabaysan yihiin qaabab joogto ah sida duubabka gogosha muraayadaha iyo dhogorta muraayadaha fiberglass-ka ah. Maaddaama xoojinta ay ku buuxsantay isku dhafka resins ("qoyan-baxsan") ee qubeyska resinka oo la jiido iyada oo dhinta, gelation, ama adkeynta, ee xabagta waxaa bilaabay kulaylka dhimashada iyo astaan adag, profile la daaweeyay oo u dhiganta qaabka dhinta.

FRP Pultrusion grating waxay u qaybsantaa saddex qaybood: I-qaabka baararka, baararka T-qaabka, iyo baararka-Load-sare ee Codsiyada Duty-culus.