FRP/GRP Transparent Molded Grating

PRODUCT DESCRIPTION

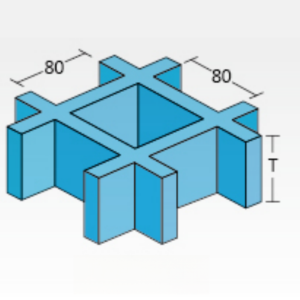

MOULDS SPECIFICATION TABLE

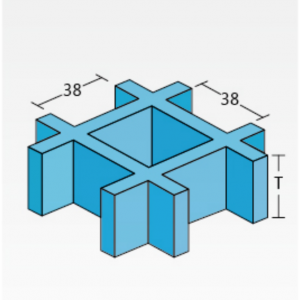

| HEIGHT (mm ) | BAR THICKNESS (mm TOP/BOTTOM) | MESH SIZE (MM) | PANEL SIZE AVAILABLE (MM) | WEIGHT(KG/m²) | OPEN RATE(%) |

| 13 | 6.0/5.0 | 38*38 | 1220*2440/1220*3660/1220*4000/1000*3000/921*3055 | 6 | 78 |

| 14 | 6.0/5.0 | 38*38 | 1220*2440/1220*3660/1220*4000/1000*3000/921*3055 | 6.5 | 78 |

| 15 | 6.0/5.0 | 38*38 | 1220*2440/1220*3660/1220*4000/1000*3000/921*3055 | 7 | 78 |

| 20 | 6.0/5.0 | 38*38 | 1220*2440/1220*3660/1220*4000/1220*4038/1000*2000/1000*3000/921*3055 | 9.8 | 65 |

| 25 | 6.5/5.0 | 38*38 | 1220*2440/1220*3660/1220*4000/1220*4038/1000*2000/1000*3000/915*3050/921*3055 | 12.5 | 68 |

| 25 | 7.0/5.0 | 38*38 | 1000*4000 | 12.5 | 68 |

| 30 | 6.5/5.0 | 38*38 | 1220*2440/1220*3660/1220*4000/1220*4038/1000*2000/1000*3000/921*3055 | 14.6 | 68 |

| 30 | 7.0/5.0 | 38*38 | 1000*4000/1220*4000 | 16 | 68 |

| 38 | 6.5/5.0 | 38*38 | 1220*2440/1220*3660/1220*4000/1220*4920/1000*2000/1000*3000/1000*4038/921*3055/915*3050/1524*3660 | 19.5 | 68 |

| 38 | 7.0/5.0 | 38*38 | 1000*4000/1220*4000 | 19.5 | 68 |

| 63 | 12.0/8.0 | 38*38 | 1530*4000 | 52 | 68 |

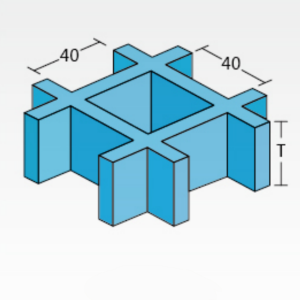

| 25 | 6.5/5.0 | 40*40 | 1007*3007/1007*2007/1007*4047/1247*3007/1247*4047/1207*3007 | 12.5 | 67 |

| 25 | 7.0/5.0 | 40*40 | 1007*4007 | 12 | 67 |

| 30 | 6.5/5.0 | 40*40 | 1007*3007/1007*2007/1007*4047/1247*3007/1247*4047/1207*3007 | 14.6 | 67 |

| 30 | 7.0/5.0 | 40*40 | 1000*4000 | 15 | 67 |

| 38 | 7.0/5.0 | 40*40 | 1007*2007/1007*3007/1007*4047/1247*3007/1247*4047/1207*3007 | 19.2 | 67 |

| 40 | 7.0/5.0 | 40*40 | 1007*2007/1007*3007/1007*4007/1007*4047/1207*3007/1247*3007/1247*4047 | 19.5 | 67 |

| 50 | 7.0/5.0 | 40*40 | 1007*2007/1007*3007/1007*4047/1207*3007/1247*3007/1247*4047 | 25.0 | 58 |

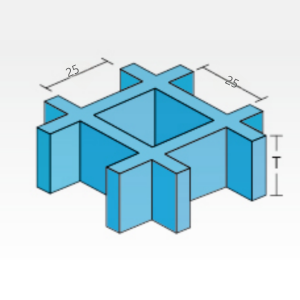

| 30 | 7.0/5.0 | 25*25 | 1000*4000 | 16 | 58 |

| 40 | 7.0/5.0 | 25*25 | 1200*4000 | 22 | 58 |

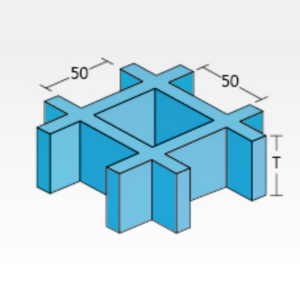

| 50 | 8.0/6.0 | 50*50 | 1220*2440/1220*3660/1000*2000/1000*3000 | 24 | 78 |

| 50 | 7.2/5.0 | 50*50 | 1220*2440/1220*3660/1000*4000/1000*3000 | 21 | 78 |

| 13 | 10.0/9.0 | 80*80 | 1530*3817/730*1873 | 5.5 | 81 |

| 14 | 10.0/9.0 | 80*80 | 1530*3817/730*1873 | 6 | 81 |

| 15 | 10.0/9.0 | 80*80 | 1530*3817/730*1873 | 6.5 | 81 |

FRP Resins Systems Choices:

Phenolic resin (Type P): The best choice for applications requiring max fire retardant and low smoke emissions such as oil refineries, steel factories, and pier decks.

Vinyl Ester (Type V): withstand the strict chemical environments used for chemical, waste treatment, and foundry plants.

Isophthalic resin (Type I): Type I is a premium isophthalic polyester resin. It is a popular choice for most applications due to its good corrosion resistance properties and relative low cost. This type of resin is most commonly used in applications where there is a possibility of a splash or spill of harsh chemicals.

General Purpose Orthothphalic resin (Type O): economic alternatives to vinyl ester and isophthalic resins products.

Food Grade Isophthalic resin (Type F): Ideally suitable for food and beverage industry factories which are exposed to strict clean environments.

Epoxy Resin(Type E):offer very high mechanical properties and fatigue resistance, taking the advantages of other resins. Mold costs are similar to PE and VE, but material costs are higher.

More mould details,please contact us!

Resins options guide:

| Resin Type | Resin Option | Properties | Chemmical Resistance | Fire Retardant(ASTM E84) | Products | Bespoke Colors | Max ℃ Temp |

| Type P | Phenolic | Low Smoke and Superior Fire Resistance | Very Good | Class 1, 5 or less | Molded and Pultruded | Bespoke Colors | 150℃ |

| Type V | Vinyl Ester | Superior Corrosion Resistance and Fire Retardant | Excellent | Class 1, 25 or less | Molded and Pultruded | Bespoke Colors | 95℃ |

| Type I | Isophthalic polyester | Industrial Grade Corrosion Resistance and Fire Retardant | Very Good | Class 1, 25 or less | Molded and Pultruded | Bespoke Colors | 85℃ |

| Type O | Ortho | Moderate Corrosion Resistance and Fire Retardant | Normal | Class 1, 25 or less | Molded and Pultruded | Bespoke Colors | 85℃ |

| Type F | Isophthalic polyester | Food Grade Corrosion Resistance and Fire Retardant | Very Good | Class 2, 75 or less | Molded | Brown | 85℃ |

| Type E | Epoxy | Excellent corrosion resistance and fire retardant | Excellent | Class 1, 25 or less | Pultruded | Bespoke Colors | 180℃ |

According to the different environments and applications, chosen different resins, we also could provide some advices!

CASE STUDIES

FRP Transparent Grating – Innovative Material, Versatile Applications

Advantages

●Light Transmission & Energy Saving

●Corrosion & Weather Resistance

●Lightweight & High Strength

●Non-Conductive & Flame Retardant

FRP Gratings are used in Construction & Infrastructure such as light-transmitting roofs and skylights for shopping malls, stadiums, and atriums, besides, aslo in agriculture & environmental Protection like Greenhouse roofing with balanced shading and natural light diffusion.

we offer custom solutions and end to end suport!