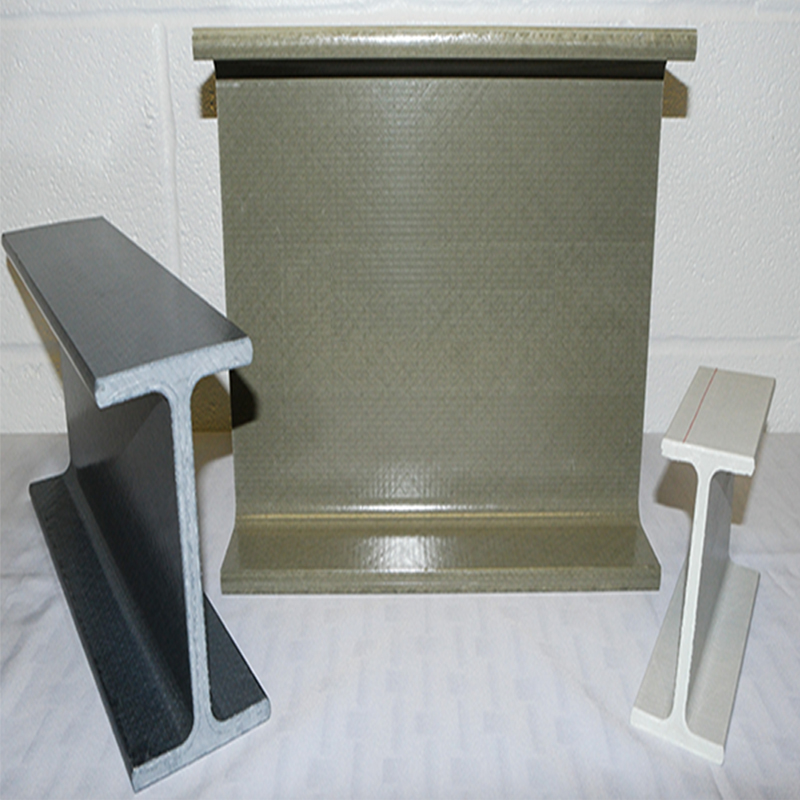

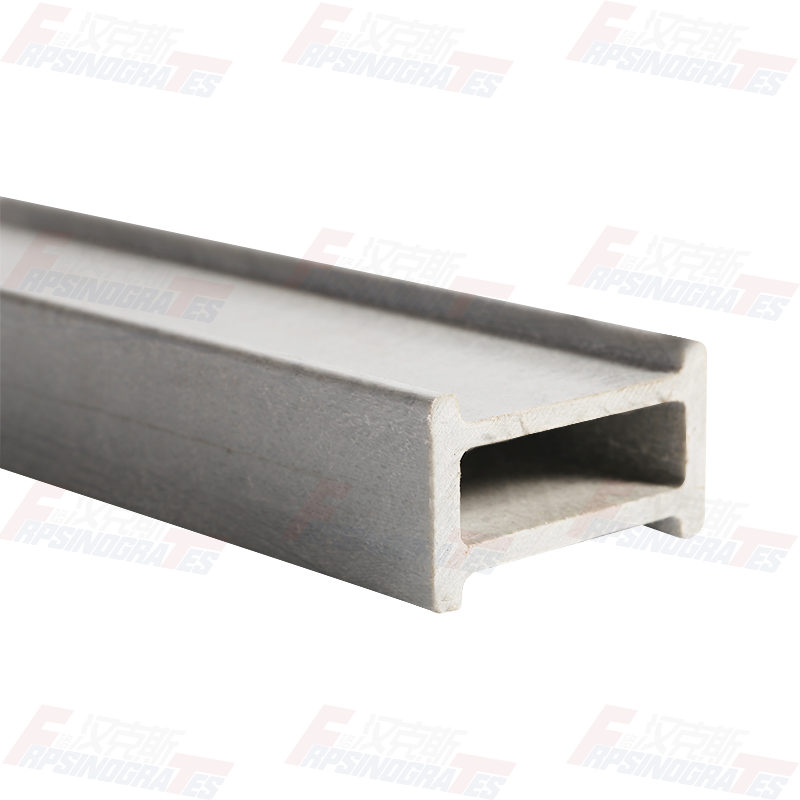

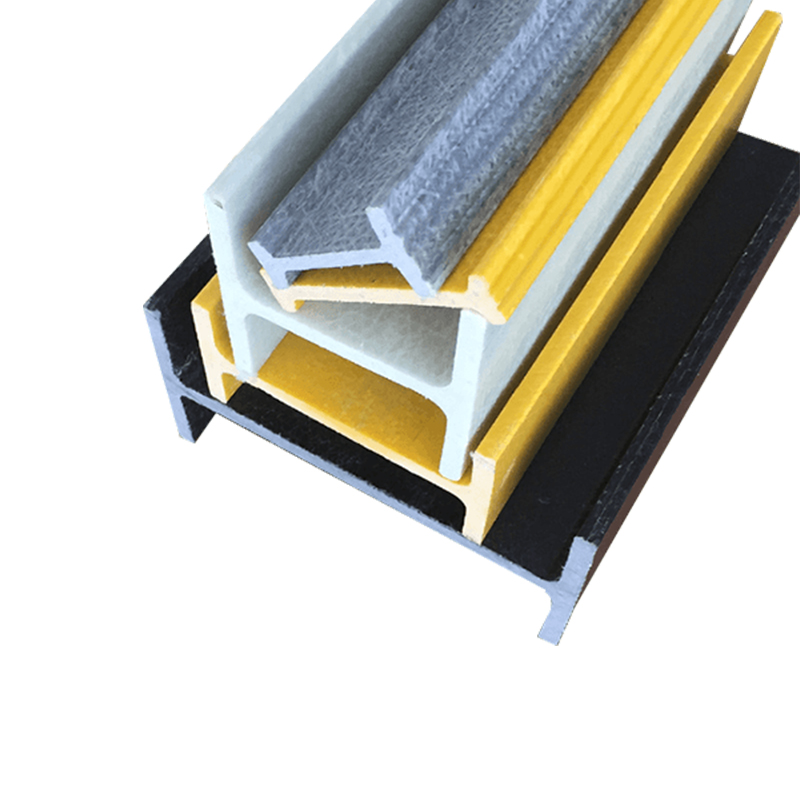

FRP/GRP High strength Fiberglass pultruded I-Beams

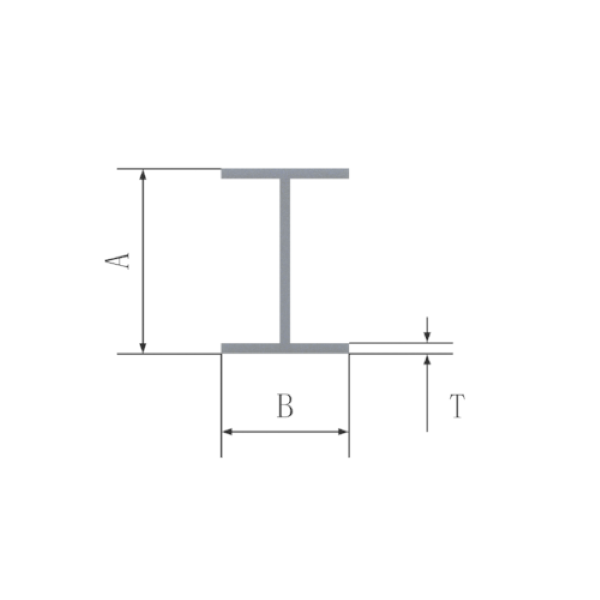

Fiberglass I - Beam Moulds Types:

| Serial Items | AXBXT(mm) | Weight g/m | Serial Items | AXBXT(mm) | Weight g/m |

| 1 | 25X8.0X4.0 | 200 | 15 | 70X15X5.0 | 860 |

| 2 | 25X15X4.0 | 366 | 16 | 100X50X8.0 | 2750 |

| 3 | 25X15X4.2 | 390 | 17 | 102X51X6.4 | 2450 |

| 4 | 25X30X3.6 | 445 | 18 | 102X102X6.4 | 3570 |

| 5 | 30X15X4.0 | 395 | 19 | 150X80X10 | 5360 |

| 6 | 30X15X4.3 | 425 | 20 | 150X100X10 | 6300 |

| 7 | 38X15X4.0 | 486 | 21 | 150X125X8.0 | 5450 |

| 8 | 38X15X4.2 | 498 | 22 | 150X150X9.5 | 7800 |

| 9 | 40X30X3.6 | 547 | 23 | 200X100X10 | 7250 |

| 10 | 50X15X4.5 | 610 | 24 | 200X100X12 | 8600 |

| 11 | 50X25X4.0 | 820 | 25 | 200X120X10 | 7980 |

| 12 | 50X101X6.3 | 2300 | 26 | 200X200X13 | 13900 |

| 13 | 58X15X4.6 | 670 | 27 | 203X203X9.5 | 10500 |

| 14 | 58X15X5.0 | 750 | 28 | 250X200X10 | 11650 |

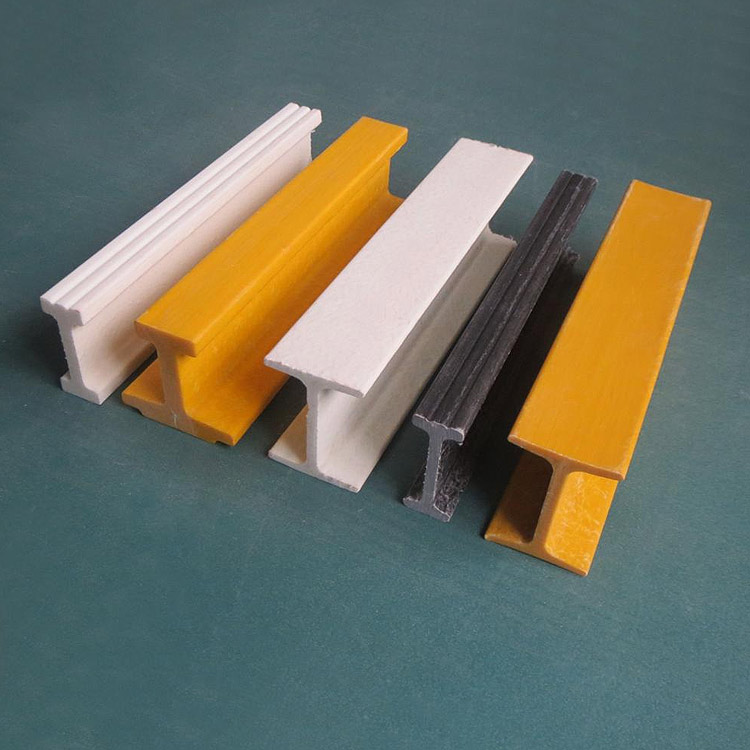

Sinogrates@GFRP PULTRUSION:

•Light

•Insulation

•Chemical resistance

•Fire retardant

•Anti-slip surfaces

•Convenient for installation

•Low maintenance cost

•UV protection

•Dual strength

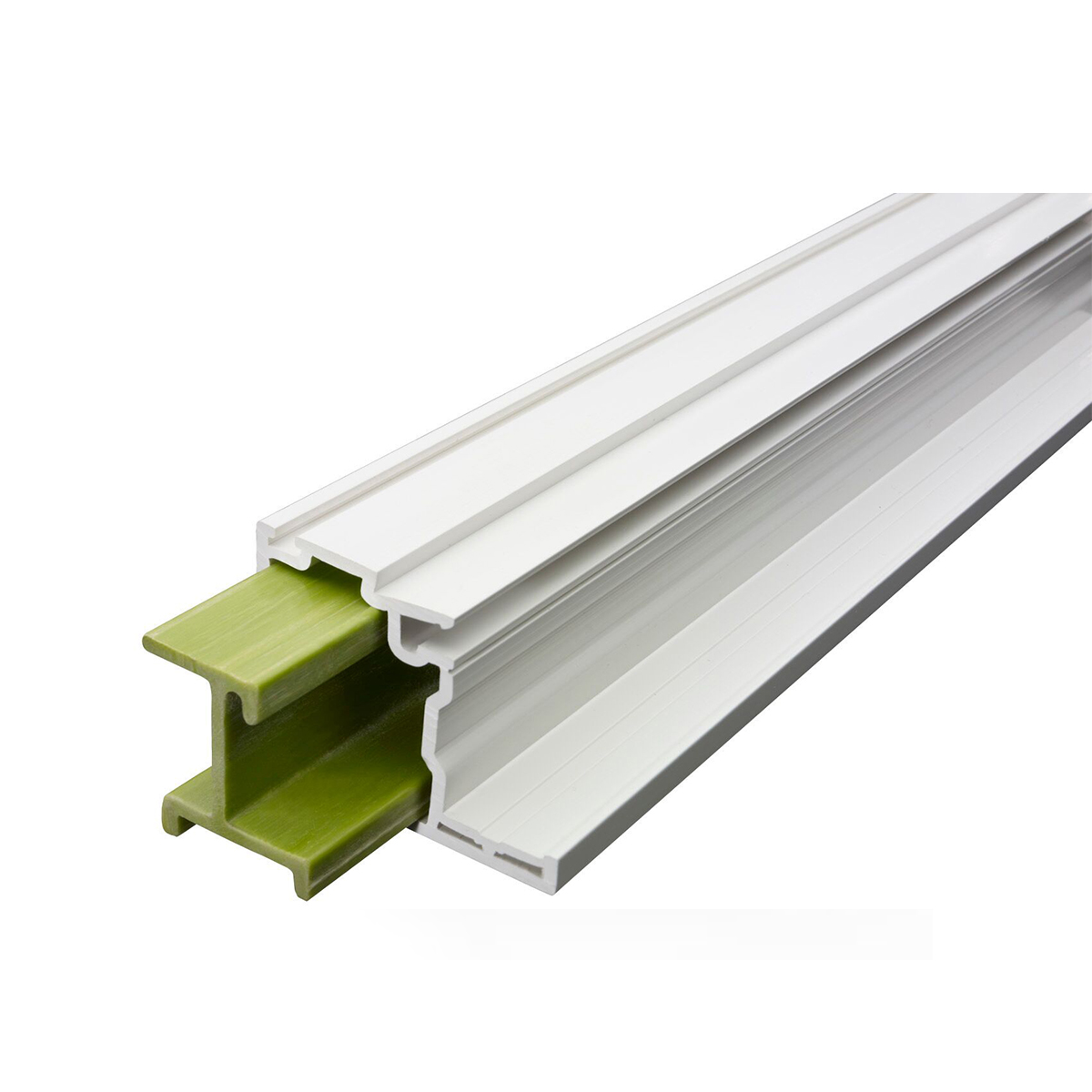

Sinogrates is a major manufacturer of fiberglass reinforced polymer (FRP) beams, which are widely used in the construction of superstructures. FRP beams are ideal for harsh environments where chemical exposure is a concern, such as outdoor walkways on drilling platforms, wastewater treatment plants, livestock facilities, and other places where secure and durable walking surfaces are needed.

FRP beams offer immense advantages over traditional steel structures, especially in areas where moisture is present. FRP beams are corrosion-resistant and will not rust, making them the ideal choice for these types of applications. In addition, FRP beams are lightweight, making them easier to transport and install. They also have excellent strength-to-weight ratios, making them capable of supporting heavy loads.

Overall, FRP beams are an excellent choice for any application where corrosion resistance and durability are needed. Sinogrates is a major manufacturer of these beams, and they are committed to providing the highest quality products and services to their customers. If you are looking for a reliable and cost-effective solution for your construction needs, Sinogrates is the perfect choice.

FRP Pultruded profiles Surfaces Opinions:

Depending on the sizes of FRP products and different environments, choosing different surface mats can achieve maximum performance to save costs to a certain extent.

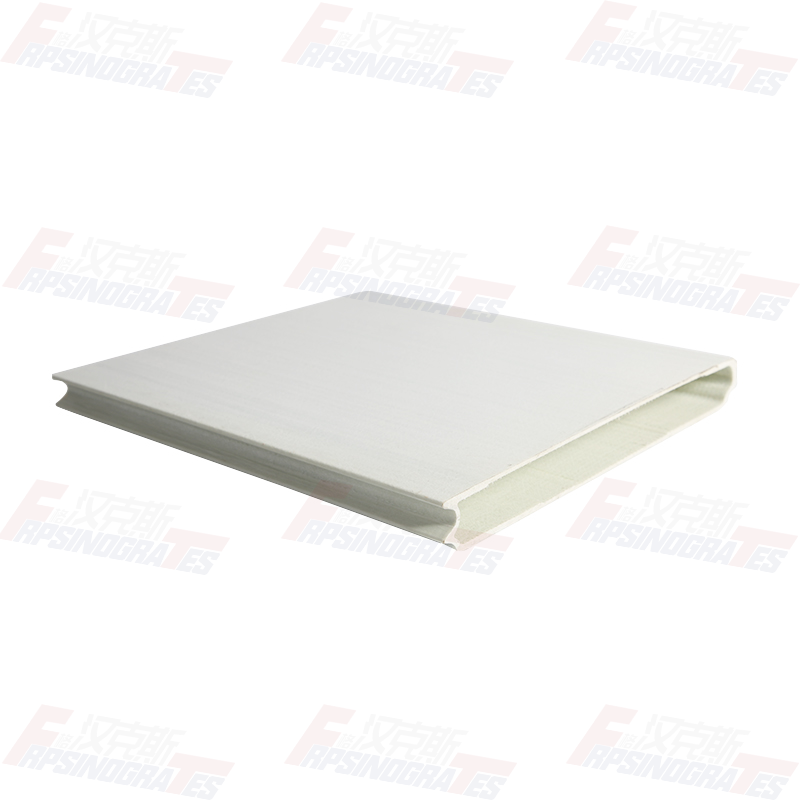

Continuous Synthetic Surfacing Veils:

Continuous Synthetic Surfacing Veils is a commonly used pultruded profiles surface. The continuous composite surface felt is a silk fabric synthesized by continuous felt and surface felt. It can ensure the strength while making the surface more gloss and delicate. When touching the product, the person's hands will not be stabbed by glass fiber. The price of this profile is relatively high. Generally, it is used in places where people are touched by handrane fences, ladder climbing, toolproofs, and park landscapes. A considerable proportion of anti -ultraviolet reagents will be added during the production process. It can ensure that it does not fade for a long time and has good anti -aging performance.

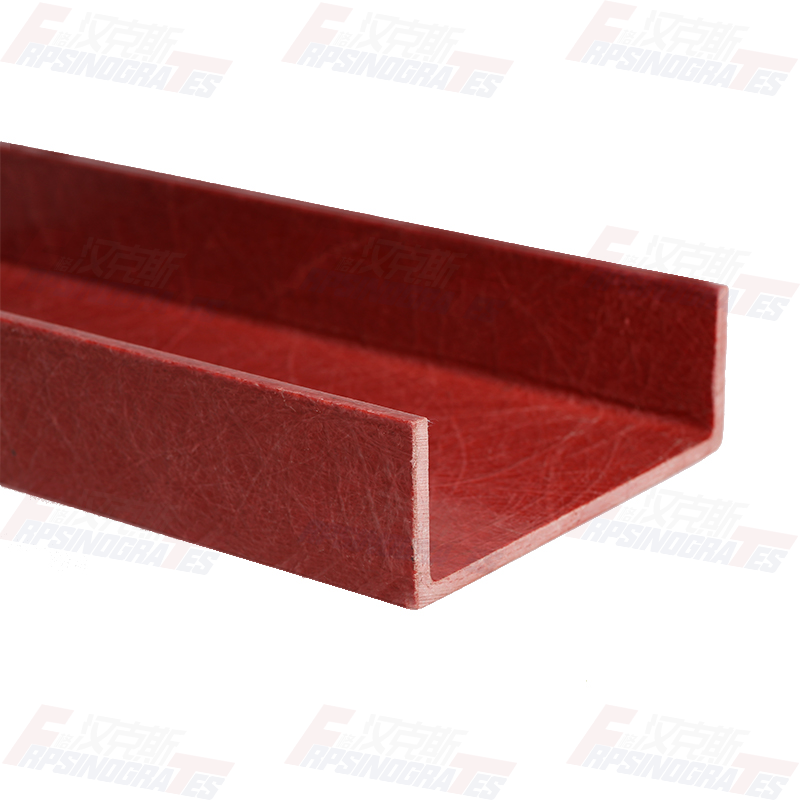

Continuous strand mats:

Continuous strand mats is the surfaces commonly used in large pultruded profiles. Continuous strand mat has a high intensity and strength advantage. It is generally used in large structural pillars and beams. The surfaces of the Continuous strand mat is relatively rough. It is generally used in industrial supporting part to replace steel and aluminum at the venue of corrosion resistance. The use of practical large -scale profiles is used in the structures that people do not often touch. This kind of profile has good costs performance. It is suitable for large -scale applications in engineering. It can effectively reduce the cost of use and ensure the performance of the product.

Continuous compound strand mats:

Continuous compound strand mat is a fiberglass fabric waving composed of surfacing veils and continuous strand mats,which has excellent strength and nice appearance. It can effectively help to reduce the costs . It is the most economical choices if high-intensity and appearance requirements. It can also be applied to the handrail protection engineering. It can effectively exert the strength advantage and have people's hand touching protection.

Wood Grain Continuous Synthetic Surfacing Veils:

Wood Grain Continuous Synthetic Surfacing Veils is one kind of fiberglass fabric waving

It has excellent strength performance which is similar to wood products. It is a substitute for wood products such as landscapes, fences, villa fences, villa fences, etc. The product is similar to the appearance of wood products and is not easy to rot, not easy to fade, and low maintenance costs in the later period. There is a longer life life in the seaside or long -term sunlight.

Synthetic Surfacing Veil

Continuous Strand Mat

Continuous Strand Mat & Surface felt

Wood Grain Continuous Synthetic Surfacing Veils

Products capacities test laboratory:

The meticulous experimental equipment for FRP pultruded profiles and FRP molded gratings ,such as flexural tests,tensile tests,compression tests, and destructive tests. According to customers’ requirements,we will conduct performances & capacities tests on FRP products ,keeping the records to guarantee the quality stability for long-term.meanwhile, We are always researching & developing innovative products with testing the reliability of FRP product performance. We can ensure that the quality can satisfy customers’ requirements stably to avoid unnecessary after-sales problems.

FRP Resins Systems Choices:

Phenolic resin (Type P): The best choice for applications requiring max fire retardant and low smoke emissions such as oil refineries, steel factories, and pier decks.

Vinyl Ester (Type V): withstand the strict chemical environments used for chemical, waste treatment, and foundry plants.

Isophthalic resin (Type I): A nice choice for applications where chemical splashes and spills are a common occurrence.

Food Grade Isophthalic resin (Type F): Ideally suitable for food and beverage industry factories which are exposed to strict clean environments.

General Purpose Orthothphalic resin (Type O): economic alternatives to vinyl ester and isophthalic resins products.

Epoxy Resin(Type E):offer very high mechanical properties and fatigue resistance, taking the advantages of other resins. Mold costs are similar to PE and VE, but material costs are higher.

Resins options guide:

| Resin Type | Resin Option | Properties | Chemmical Resistance | Fire Retardant(ASTM E84) | Products | Bespoke Colors | Max ℃ Temp |

| Type P | Phenolic | Low Smoke and Superior Fire Resistance | Very Good | Class 1, 5 or less | Molded and Pultruded | Bespoke Colors | 150℃ |

| Type V | Vinyl Ester | Superior Corrosion Resistance and Fire Retardant | Excellent | Class 1, 25 or less | Molded and Pultruded | Bespoke Colors | 95℃ |

| Type I | Isophthalic polyester | Industrial Grade Corrosion Resistance and Fire Retardant | Very Good | Class 1, 25 or less | Molded and Pultruded | Bespoke Colors | 85℃ |

| Type O | Ortho | Moderate Corrosion Resistance and Fire Retardant | Normal | Class 1, 25 or less | Molded and Pultruded | Bespoke Colors | 85℃ |

| Type F | Isophthalic polyester | Food Grade Corrosion Resistance and Fire Retardant | Very Good | Class 2, 75 or less | Molded | Brown | 85℃ |

| Type E | Epoxy | Excellent corrosion resistance and fire retardant | Excellent | Class 1, 25 or less | Pultruded | Bespoke Colors | 180℃ |

According to the different environments and applications, chosen different resins, we also could provide some advices!

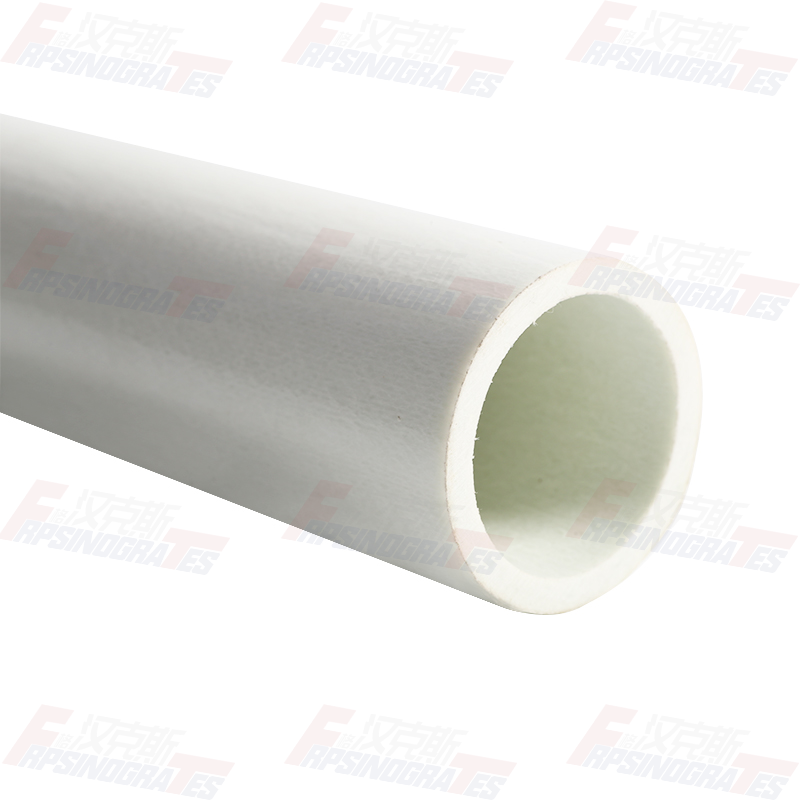

According to the applications, handrails can be used in various environments:

•Cooling Towers •Architecture Solutions •Highway Signs

•Utility Markers •Snow Markers •Marine/Offshore

•Hand Rails •Stairs & Accessways •Oil & Gas

•Chemical •Pulp & Paper •Mining

•Telecommunications •Agriculture •Hand Tools

•Electrical •Water & Wastewater •Custom Applications

•Transportation/Automotive

•Recreation & Waterparks

•Commerical/Residential Construction

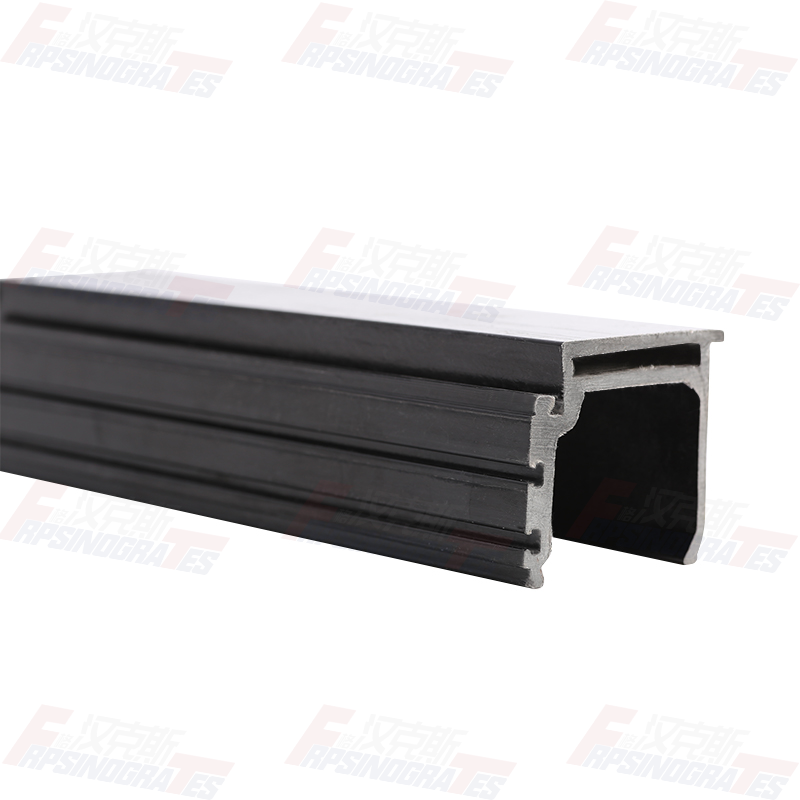

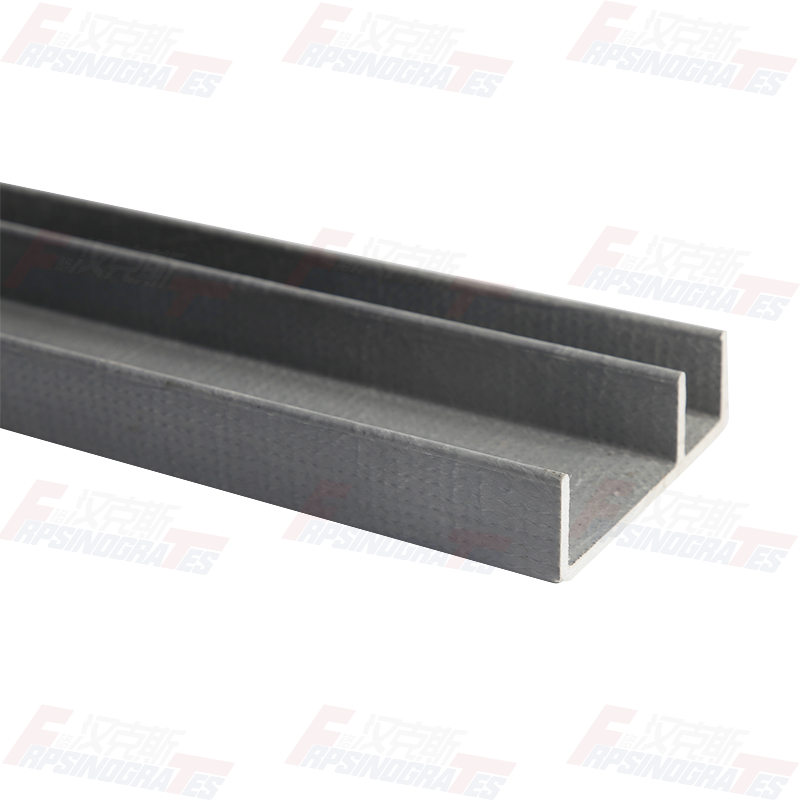

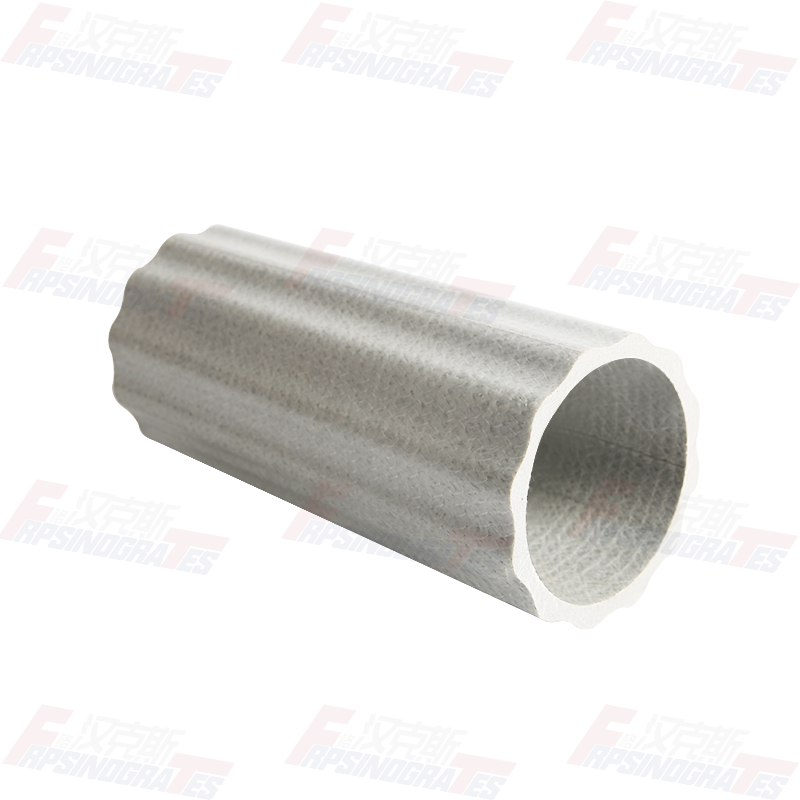

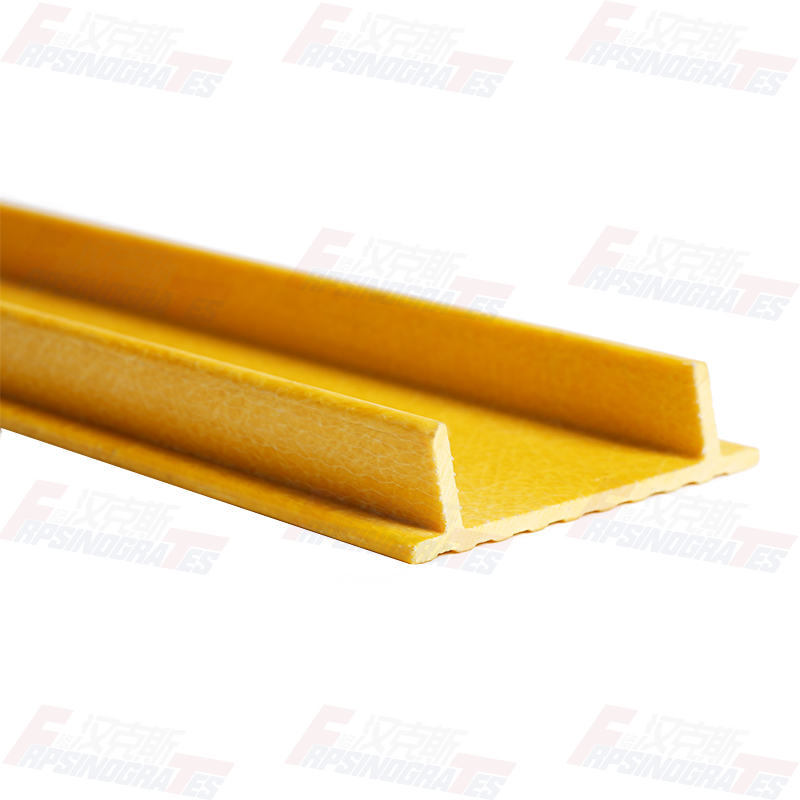

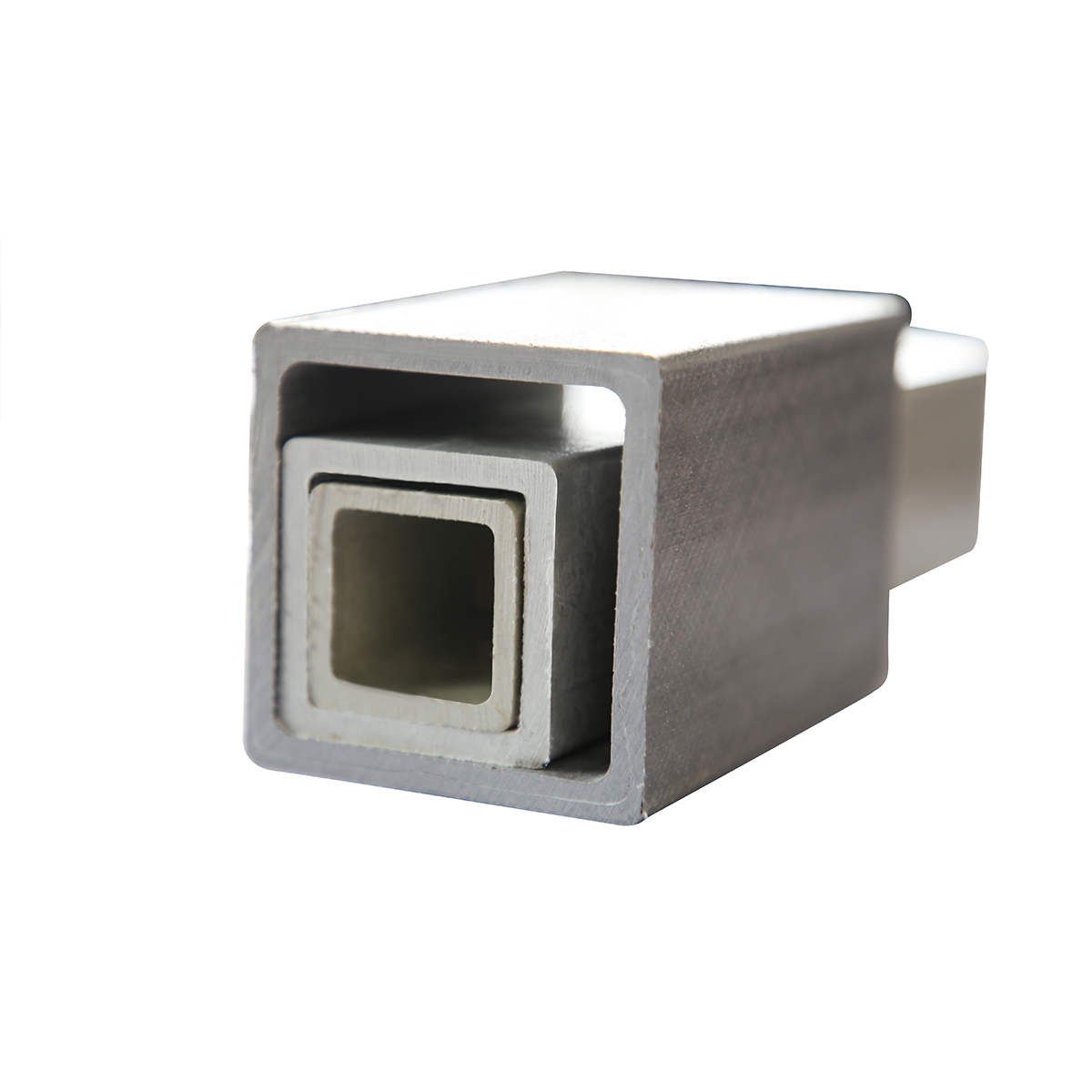

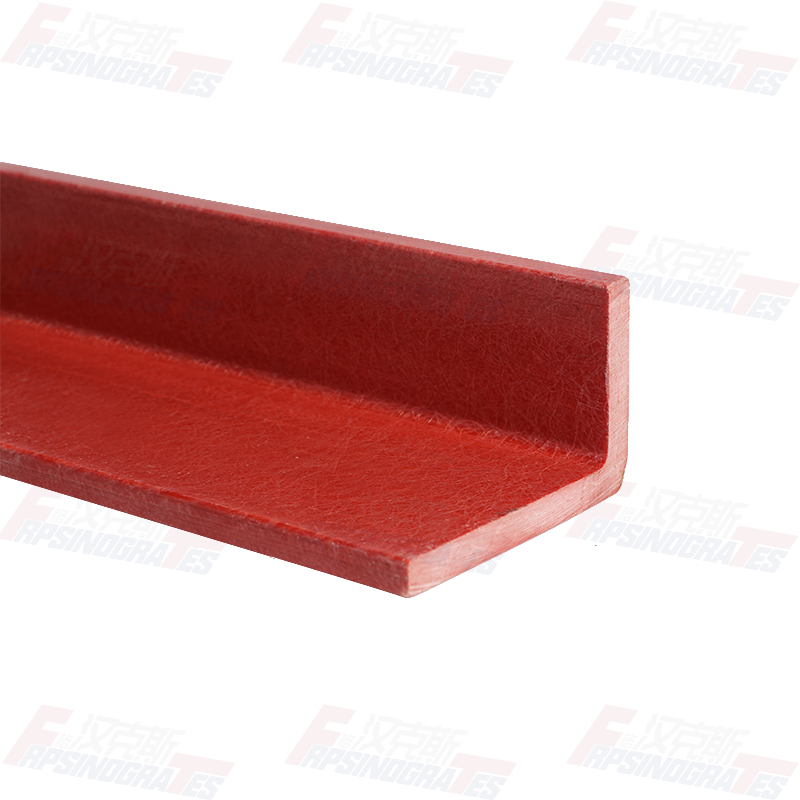

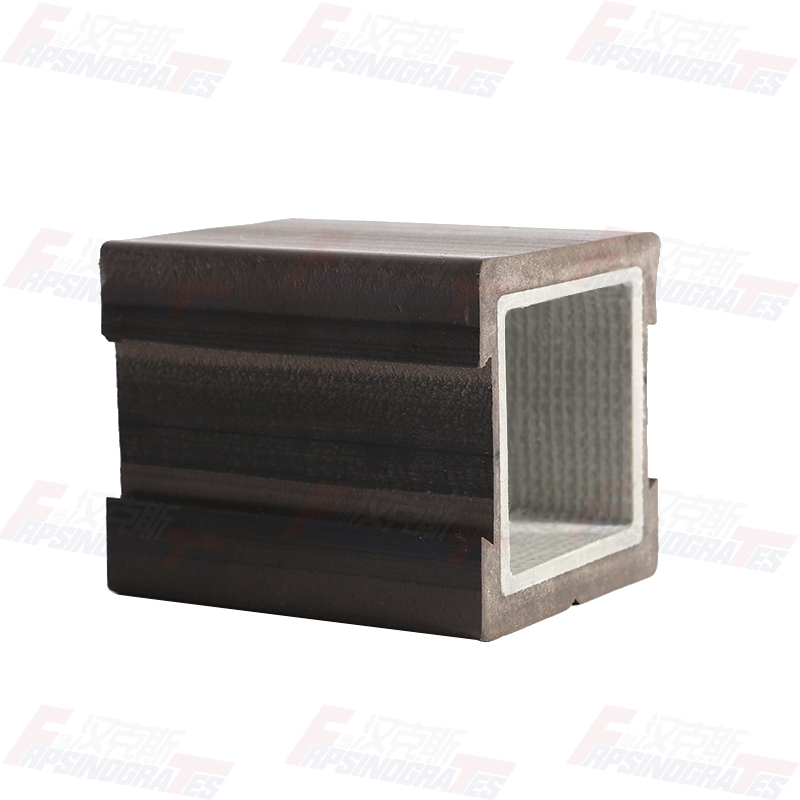

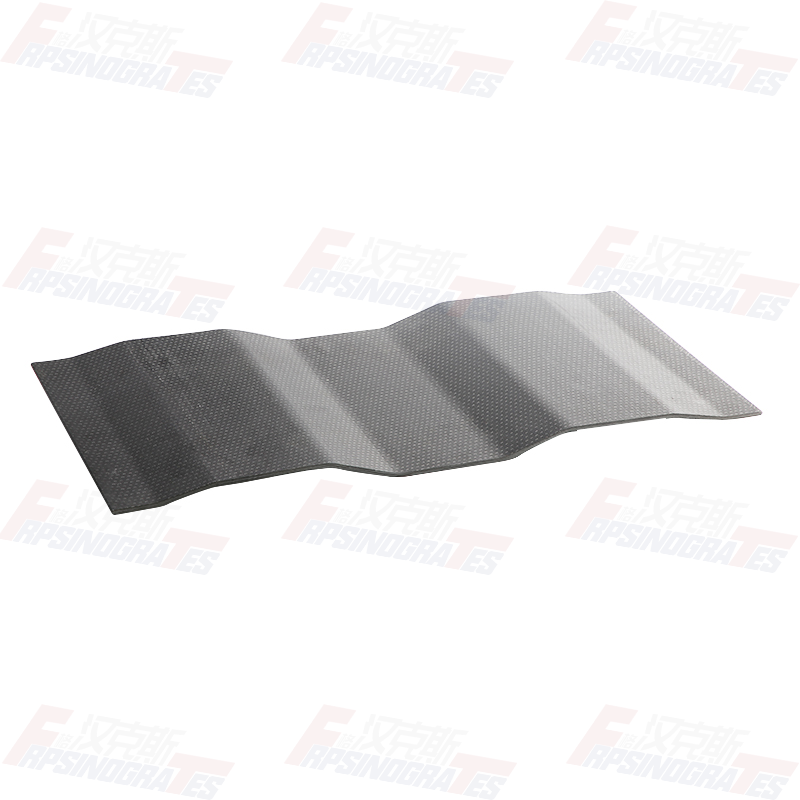

Parts of FRP pultruded profiles exhbitions :