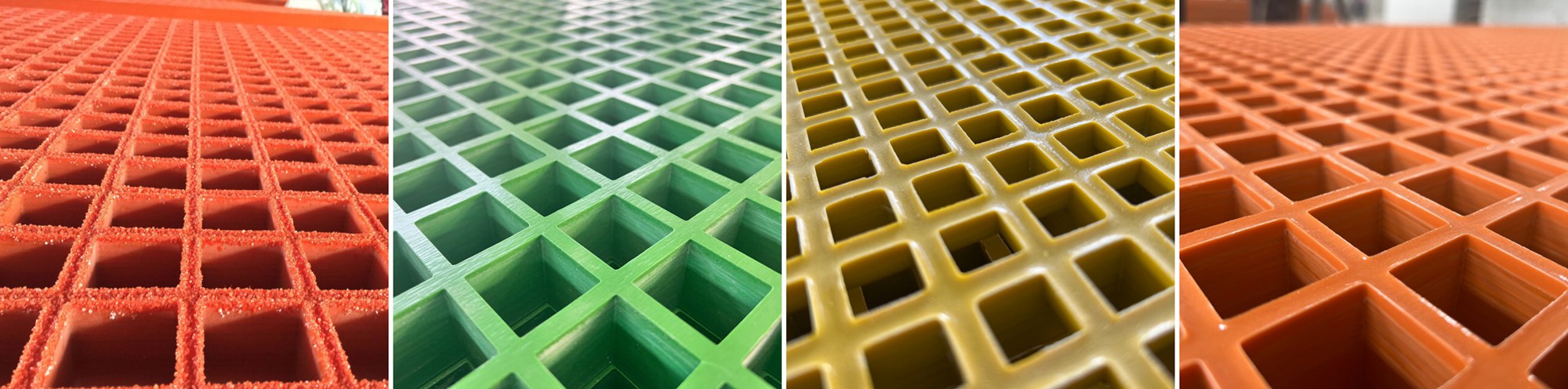

When specifying FRP (Fiberglass Reinforced Plastic) grating for industrial applications, most engineers focus on technical specifications like load capacity, resin type, and mesh size.However, at SINOGRATES, we know color selection plays a surprisingly strategic role in maximizing project value. Here’s how to make informed color choices:

1. Safety & Visibility

• Yellow: The industry standard for hazard identification

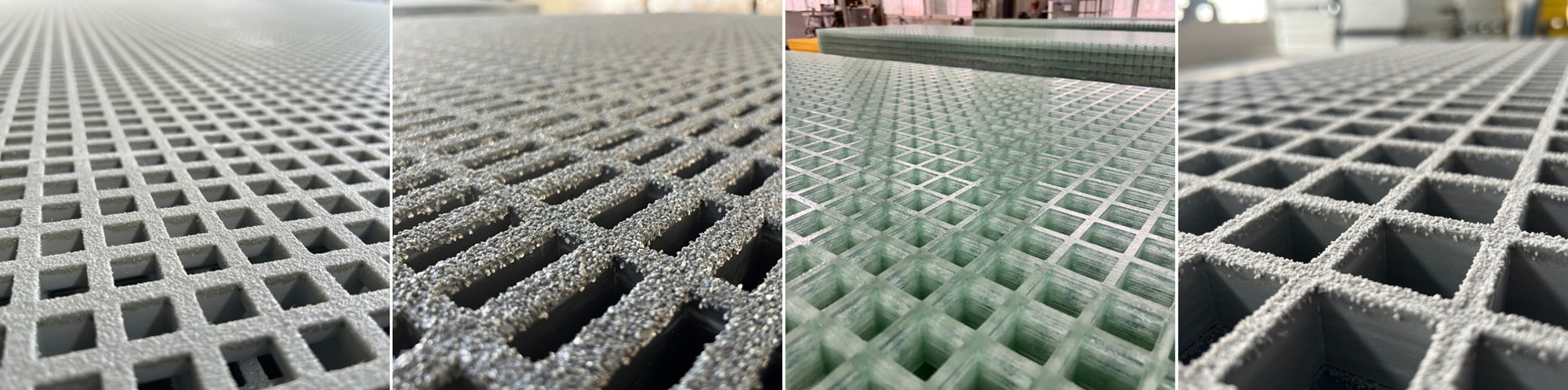

• Grey: Blends with concrete for low-visibility areas

• Blue: Excellent contrast for food/pharma cleanrooms

• Green: High visibility in outdoor environment

•Transparent/ Clear

Light Transmission:

80-90% natural light penetration (ideal for rooftops, greenhouses).

2. Thermal Performance

Lighter colors (white/beige) reflect heat (↓ surface temp by 15-20°F vs dark colors) – crucial for chemical plants and sunny climates.

3. Brand Alignment

Our custom color-matching service lets clients coordinate grating with:

• Corporate identity colors

• Facility zoning systems

• Safety protocol color codes

4. Maintenance Considerations

• Dark hues (black/dark grey) better conceal:

• Oil stains in automotive facilities

• Dirt accumulation in wastewater plants

• Chemical discoloration in processing units

5. UV Stability

All our pigments contain UV inhibitors, but:

Earth tones show minimal fade over time.

Bright colors require more frequent recoating in direct sunlight.

We offer:

As one of few manufacturers offering 12 standard colors + custom solutions, we help clients:

✓ Meet OSHA/NFSI visibility requirements

✓ Reduce heat absorption energy costs

✓ Maintain aesthetic consistency across facilities

✓ Extend service life through smart color science

Post time: May-13-2025