Shabageynta Isku-xagalka Layliga ah ee Shaqada Culus GRP Molded

SHARAXA AALADAHA

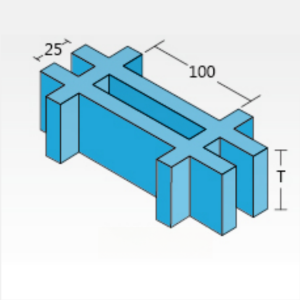

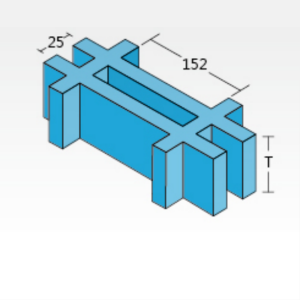

Miisaska Qeexida CARUURTA

| DHEER (mm) | dhumucda baarka (mm SARE/hoose) | Miisaanka MESH (MM) | QAABKA GOLAHA LA HELI KARO (MM) | Miisaanka (KG/m²) | QIIMAHA FURAN(%) |

| 25 | 9.5/8.0 | 25*100 | 1220*2440/1220*3660/915*3050 | 19.5 | / |

| 25 | 7.0/5.0 | 25*100 | 1220*3660/915*3050/1007*3007 | 13.8 | / |

| 25 | 10.0/8.0 | 25*100 | 1000*4000 | 13.5 | / |

| 25 | 6.5/5.0 | 25*100 | 1220*3660 | 12.50 | / |

| 28 | 7.0/5.0 | 50*100 | 1500*2000 | 11.0 | / |

| 38 | 7.0/5.0 | 38*100 | 1220*3660 | 15.50 | / |

| 25 | 7.0/5.0 | 25*150 | 998*2998 | 11.0 | / |

| 38 | 12.0/5.0 | 25*150 | 1220*3660 | 21.0 | / |

| 38 | 7.0/5.0 | 38*150 | 1220*3660 | 16.0 | / |

| 38 | 7.0/5.0 | 25*152 | 1220*2440/1220*3660/915*3050 | 22.8 | / |

| 50 | 12.0/9.0 | 25*50 | 1220*3660 | 48.0 | / |

| 40 | 7.0/5.0 | 40*80 | 998*1998 | 15.0 | / |

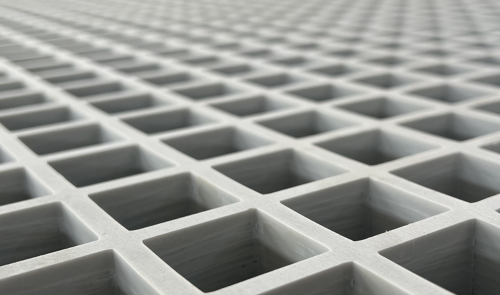

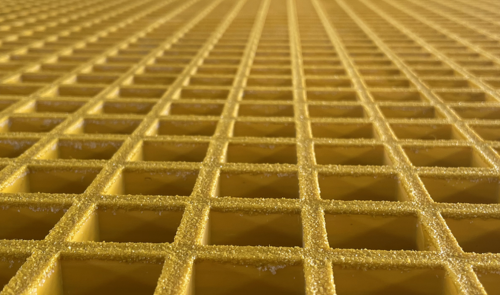

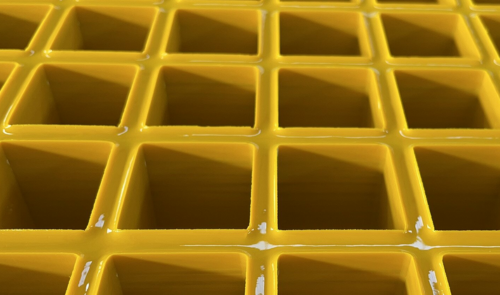

Xulashada dusha sare ee FRP qaabaysan:

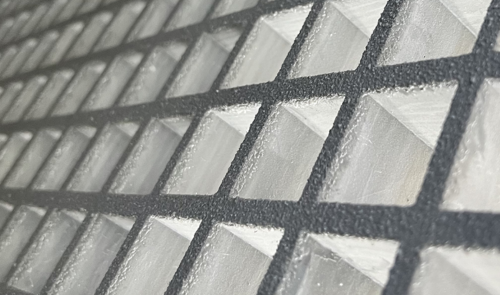

Dabaqa sare

Heerka Grit

Fine Grit

Dhammaystir Concave

● Dhul siman oo siman oo sare oo siman

●Standard Grit Halbeegga grit ee ilaalinta silbashada

●Cancave Surface Dhamaystir dabiici ah oo leh muuqaal yar oo daboolan oo ku yaal baararka rarka

Dusha sare ee qashin-qubka ah Dhammays tiran oo dusha sare ah oo u baahan in korka dhulka la dhigosiman si aad meesha uga saarto dhamaadka concag ka hor inta aanad marin ciid wanaagsan.

Doorashooyinka Nidaamyada Resins ee FRP:

Xabagta phenolic (Nooca P)Doorashada ugu fiican ee codsiyada u baahan dab-demiska ugu sarreeya iyo qiiqa sii daaya ee hooseeya sida warshadaha saliidda, warshadaha birta, iyo sagxadaha.

Vinyl Ester (Nooca V): u adkeyso jawiga adag ee kiimikaad ee loo isticmaalo kiimikaad, daaweynta qashinka, iyo dhirta cawska.

Xabagta isphthalic (Nooca I)Nooca I waa xabagta isophthalic polyester premium. Waa doorasho caan ah oo loogu talagalay codsiyada intooda badan sababtoo ah sifooyinka wanaagsan ee iska caabinta daxalka iyo qiimaha hooseeya. Xabagta noocaan ah waxaa inta badan loo adeegsadaa codsiyada halka ay suurtagal tahay in ay daadato kiimikooyin adag.

Ujeedada Guud ee Xabagta Lafaha (Nooca O): beddelka dhaqaalaha ee vinyl ester iyo alaabta resins isophthalic.

Heerka Raashinka xabagta isofthalic (Nooca F): Waxay ku habboon tahay warshadaha warshadaha cuntada iyo cabitaanka kuwaas oo soo gaadhay deegaan nadiif ah oo adag.

Epoxy Resin (Nooca E):bixiyaan sifooyin farsamo oo aad u sarreeya iyo iska caabin daal, qaadashada faa'iidooyinka resins kale. Kharashyada caaryada waxay la mid yihiin PE iyo VE, laakiin kharashyada alaabta ayaa ka sarreeya.

Hagaha ikhtiyaarka resins:

| Nooca Resin | Xulashada xabagta | Guryaha | Iska caabinta Kiimikada | Dab-demiska (ASTM E84) | Alaabta | Midabada hadalka | Heerkulka ugu sarreeya ℃ |

| Nooca P | Phenolic | Qiiqa Hoose iyo Iska caabinta Dabka Sare | Aad u Wanaagsan | Fasalka 1, 5 ama ka yar | Qaboojiyay oo Barooray | Midabada hadalka | 150 ℃ |

| Nooca V | Vinyl Ester | Iska caabinta Daxalka Sare iyo Dib u Celinta Dabka | Aad u fiican | Fasalka 1, 25 ama ka yar | Qaboojiyay oo Barooray | Midabada hadalka | 95℃ |

| Nooca I | Polyester-ka isophthalic | Iska caabinta Daxalka Fasalka Warshadaha iyo Dab-demiska | Aad u Wanaagsan | Fasalka 1, 25 ama ka yar | Qaboojiyay oo Barooray | Midabada hadalka | 85℃ |

| Nooca O | Ortho | Iska caabinta Daxalka Dhexdhexaadka ah iyo Dib u Celinta Dabka | Caadi ah | Fasalka 1, 25 ama ka yar | Qaboojiyay oo Barooray | Midabada hadalka | 85℃ |

| Nooca F | Polyester-ka isophthalic | Caabbinta Daxalka Darajada Cunnada iyo Dib u Celinta Dabka | Aad u Wanaagsan | Fasalka 2, 75 ama ka yar | La qaabeeyey | Brown | 85℃ |

| Nooca E | Epoxy | Iska caabin daxalka oo aad u wanaagsan iyo dab-demiska | Aad u fiican | Fasalka 1, 25 ama ka yar | Barooran | Midabada hadalka | 180℃ |

Marka loo eego bay'ada iyo codsiyada kala duwan, ee la doortay ee resins kala duwan, waxaan sidoo kale ku siin karnaa xoogaa talooyin ah!

ARDAYDA KIISKA

Codsiyada:

- Sagxadaha warshadaha & lugaynta

- Dhirta farsamaynta kiimikada

- Goobaha saliidda & gaaska

- Dhismaha badda & xeebaha

- dhirta daaweynta biyaha

- Saldhigyada korantada

- Goobaha cuntada lagu farsameeyo

Ikhtiyaarada la beddeli karo:

- Cabbirka mesh & kala duwanaanta dhumucda

- Noocyada resin ee kala duwan

- Codaynta midabka